Building a better ZF!

!

Milan

0419 475 964

milan@milbac.com.au

Hi there, welcome to my blog. I am as genuine as they come in terms of sharing information. Obviously I can't disclose every detail in this blog, but I hope to convince you that I may know what I talking about - or at least in my mind :). I decided about 4 years ago try something new, pick up a hobby and it just so happened that I got stuck into the ZF gearboxes.

I'm a Chartered Electrical Engineer and employed full time - this is a hobby and I don't make money from this work. I do it because no-one seems to want to share any information.

Hopefully after reading my contribution below you will understand some of the build requirements. I appreciate feedback as long as its constructive and not rude. If you are stuck, need help or a box built - give me a call.

Lets begin...

What not to do:

Machine an input shaft bushing (custom). Why? Because the ZF intermediate is not compatible with the 6R80 input shaft. The bearing journal on the ZF intermediate does not sit deep enough in the 6R80. The bushing in the 6R80 sits further down the shaft and hence cannot hold the ZF intermediate shaft. The answer for some is to make their own bush – mostly from bronze and machine the input shaft to suit the new bush.

If you decide you want a 6R80 at the front end, then the weakness will be the intermediate shaft. You can cryo and stress relieve the intermediate shaft but I just opt for the billet intermediate to suit the 6R80 - look up TCS, off the shelf billet intermediate. It is a 6R80 intermediate and will need different parts to make it work at the back end, for a start its 24.17mm journal diameter instead of 25.17 found in turbo/n.a./terra/GT ZF's. Only the LPi I think had the 24.17intermediates or early 6HP19/21. Nevertheless the TCS shaft is good enough for 1000HP. You will break other parts of the box before the intermediate at power levels beyond 1000HP

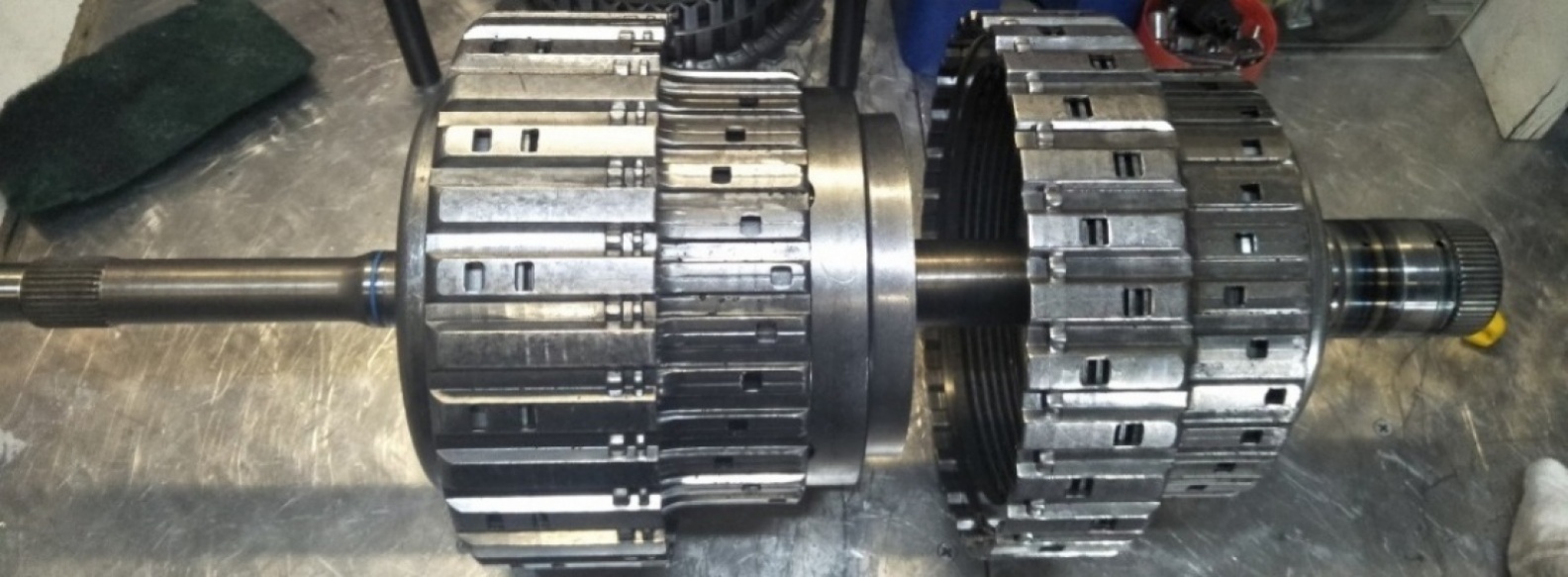

Below you will see the 6R80 intermediate bush sits deeper in the 6R80 input drum. I install the only billet intermediate 25.17mm shaft + drum that suits the 6R80 OEM input assembly.

The journal on the 6R80 is much longer, and sites deeper down the input shaft. Hence the bush you put in there is a standard bush by the OEM such as Ford, ZF or Sonnax.

The second place I see short cuts is with the machining of the input shaft journal that sits in the torque converter. A big short cut, which means you cannot swap 6R80 input shafts if needed.… you need to get it machined to suit the converter!

I slightly modify the ZF sealing rings to fit the 6R80 shaft. They provide a better seal than scarf cut Teflon seal rings.

Now, lets get back to the intermediate shaft. There are two variants to the intermediate – 24.17mm and 25.17mm diameter to be exact. The early model ZF’s and 6R60 gearboxes started out with the 24mm versions. Watch for this slight detail. The ZF is heat treated to make it stronger, but for some of the 400kW+ cars out there, this will not hold up. The standard 6R80 intermediate, being 24.17mm will not hold up either. You will need a TCS 300M Billet intermediate. However, this is not suitable for the rear planetary on the ZF. The ZF intermediate is a 30T spline on the rear planetary, whereas the 6R80 intermediate is a 29T spline.

If you are going to put a 6R80 in to ensure longevity of the transmission sitting behind a 400kW+ engine, then don’t waste time with the ZF intermediate. Yes you can get it cryogenically treated, shot peened stress relieved but its still going to break - I assure you. I’ve seen too many breaks in the 6R80 / ZF combo’s.

You can also buy billet input shafts, places like Precision Racing, Monsta Torque, Bluestreak, DSR and others sell them. Personally, I wouldn't use a billet input shaft unless I need more than 1000HP.

Billet intermediate - there is a difference

For 400kW+ I recommend a billet intermediate. There are a few options out there, suss them out for yourself. Now lets talk about the intermediate drum - ZF use a “tin can” drum, then you cut this off the ZF shaft and weld it on a custom billet shaft. Well I don't do this either!. Have a good look at the billet intermediates and you will see what I am talking about. What's the alternate?

Option 1: ZF/6R80 billet intermediate. I spent some time desiging this shaft to suit both a ZF planetary and 6R80 planetary i.e. suited for caged bearing (6R80) and open bearing (ZF). The only two piece billet intermediate on the market (that I have come across thus far) that suits the ZF 30T rear planetary spline. Pay close attention to the failure points on the OEM and our competitors shafts, we have no undercuts around out splines, or tapers are gentler, and our bearings surfaces take close or open torrington bearings.

The bearing runners have been designed to for open or closed Torrington bearings – this helps immensely when setting up the end play clearance during assembly. Our maraging steel is sought from the US and used specifically for the design of this shaft.

Option 2: TCS billet intermediate. It is a two piece shaft but take care – the shaft will not fit directly into a ZF rear planetary. I would only install this option due to being slightly cheaper than option 1. But it is a good alternative for getting the 1000HP capability. Here you will need to do something about the rear planetary to take the 29T spline as well as use a 24.17mm sun gear shaft.

Bushings

Bushings are detrimental to the ZF gearbox. Clearances need to be 1-2 thou” for the oil pressures to hold. The intermediate sits inside a hollow shaft, fluid leakage limited by the gap between the bushing and the journal at each end of the shaft. In our build the bushings are all replaced – there are 9 of them. Some take a bit to replace and require special tools for their removal.

Clutch Packs

This gearbox uses pistons to compress clutch packs against each other to engage the relevant gear. These moving parts of the piston cups have rubber O-rings that need to be replaced – especially if the gearbox has been subjected to extreme heating – i.e hard driving. I always replace all O-rings – it’s a painful process with various springs and compression clamps, but it means you will not have issues with moving parts.

Clutch packs. I’m not convinced that you need stage II clutch packs for 400kW applications. You can get the same performance without the cost. Certainly for the 1000+HP applications you can’t go without the Exedy Stage II kits. Raybestos have come to the party with their GPZ frictions and steels kit.

Clearances – I have my own set up but generally keep it in line with ZF for a ZF build and 6R80 for a 6R80 valve body. They have different clearances and the clutch packs are somewhat different. It will depend on what you need and how smooth you want to change gears, sometime the wave cushion plate is removed to make for a snappier gear change.

You cannot tune out the wrong clearances. Ultimately, the clutch packs need time to fill the piston cup and engage the clutch packs – they also need pressure to release the clutch packs and time to release. No amount of tuning will fix mechanical issues. Now lets talk about tuning – up the pressures you say… well, the limit is pump itself - maybe 80psi. Then your torque converter – being an e-lock will use some of that pressure to disengage the torque converter lockup.

I have seen pressures asking for 35bar! What the? Not possible. The second misconception is that the pressure is somehow regulated – well there is NO pressure sensors in the valve body. So how is pressure controlled – well its not – its set up as a feedforward controller without feedback. The only feedback the gearbox looks for is the change in OSS (output shaft speed) with the input drum speed. Based on input and output speed the gear box "learns" how to bring clutch packs on and off.

The ZF gearbox is self learning – it learns over time how long each gear takes to change, how long the fill times are between gear changes and makes its own adjustments. It takes about 200km to settle the box down. If someone tells you they have reset the learned parameters – ask how they do it. Only ZF can do the KAM reset on the TCM or PCMTEC with the Workshop Version. Whiteford and BPR also do re-progarmming and bootloaders etc (from what i have read in forums).

Torque truncation – torque removal. If you want to kill the gearbox fast, then remove the torque reducers. Rather than removing it altogether, try running with harder shifts with some torque truncation. It will actually change gears quicker by pulling back the engine torque.

Valve bodies - require some considerations

These babies are quite complex and require some attention. Its not good practice to pull them apart unless there are specific issue. There are numerous valves and solenoids that may need replacing. However, these are rare. I don’t use the sonnax Zip kits unless I really need to, but you need to pull the two halves apart to find out if you need them. Zip kits don’t solve all the problems, but it’s a easy first start – they eliminate leaks from the valve body end chambers and hence improve the valve body operation. Other upgrades here are from Sonnax, Transgo and shift right. These are costly upgrades and in some cases an overhauld valve body is recommended – its just a case by case basis. Solenoid should be replaced when they go green or don’t test for vacuum fitness. Solenoids should de replaced with genuine ZF parts.

Your build requirements

Now lets talk about handling big power in the gearbox – up to 1000HP you will need:

- 6R80 input shaft, cryogenically treated to hardened, shot peen to stress relieve.

- 4 pinion planetary – as found in all 6R80’s. Ford USA improved on the 3 pinion ZF planetary as a failure mode. It simply has a better power handling spreading the torque across 4 sun gears instead of 3. The carrier is much stronger also. Bluestreak make a billet planetary set but refused to sell it to me, so if you can get your hands on one then please get one. I've been buying mine from the U.S.A. yep i know doesn't make sense.

- Billet intermediate.

- Bushes and o-ring replaced - get the ZF overhaul kit. Transtec kit is also good.

- For the 1000HP application we will need to put in the needle roller bearing on the pump to carry the torque converter. Otherwise the solid bush will be pulled out (unless you have a really stiff flex plate!). These are hard to get - look out for them.

- 6R80 pump is included for the 6R80 input shaft.

- New torque converter to suit 6R80 front end, get hub with flats and Tangs.

What does all this mean to the buyer – well you have gearbox assembled by someone who cares – I don’t do this for a living but for the passion. I was where most people are – being told "to buy this, buy that, give me a week for this, give me a week for that, this can’t be done, that cant be done". I can rebuild these boxes in a day or so and have all the necessary tools.

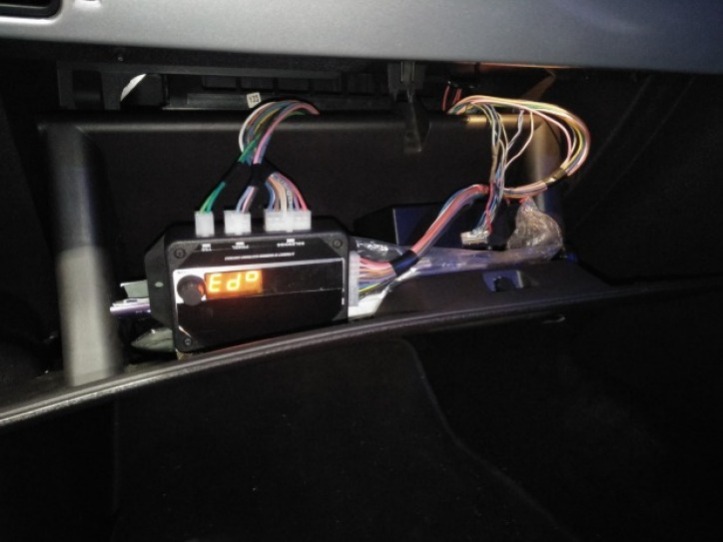

I've also built a 6R80 box using the US SHift Quick 6 controller. To work with the stick shifter additional electronics is required as well as extra wiring with the Ford PCM. You can do your own research – look up USShift Quick 6. Almost everything in your ZF case gets put in the bin. Obviously, you cannot just buy the 6R80 from the U.S. as it will not have the correct bell housing. I have done and run two Quick6 setups. For this build you will need the ZF case, modifications to set up the cabin shifter, some welding of the case to take the bias spring, some machining to fit the OWC, Gen II Valve Body and wiring interface with the existing ECU and tune. You get software to set up your own shift tables as a bonus you get transbrake!. I don’t believe anyone else in Australia has done this yet - drop me a line if you have, I'm keen to exchange info.

Get in touch

email or call me anytime - details at top.